Welcome to Lean-Tool.com

We provide tools for lean manufacturing / Toyota Production System

Easy,Simple, and Powerful

Our Tools :

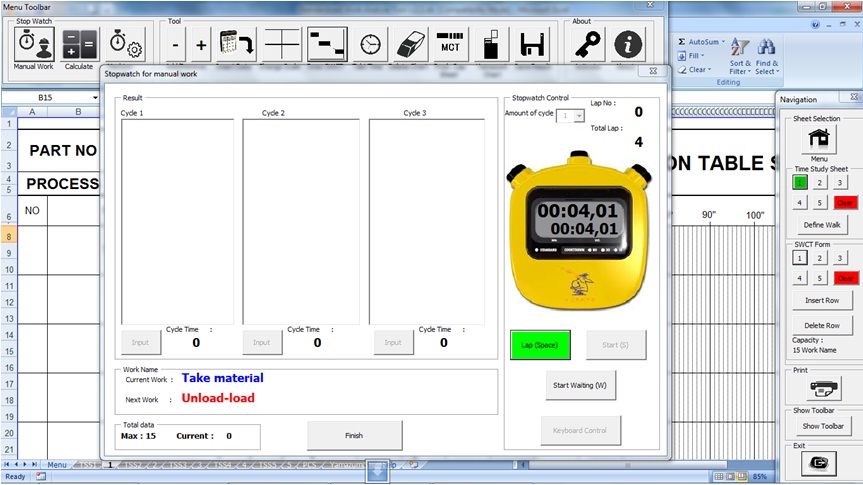

Stopwatch 100 Laps Cycle |

Standardized Work Combination Table Macro |

Standardized Work Analyze Tool (SWAT) |

Standardized Work Analyze Tool+Video Capture |

Heijunka Generator |

| OEE Monitoring System |

| Description :

OEE (Overall Equipment Effectiveness) Real Time monitoring system using Raspberry Pi Compute Module 4. |

| Video : Related Videos:

|

|

Feature:

Contact me at: yaseralie@gmail.com If you interesting to implement this system. We provide guidance for implementation this system Including code of program, excel macro for configuration and view record, and Grafana Dashboard You can copy to others machine FREE |

| The Ultimate Guide to Lean Manufacturing |

From this history of lean manufacturing to pros and cons, this in-depth guide explores everything you need to know about lean manufacturing.

Lean manufacturing boasts a holistic set of principles and tools that have stood the test of time. Read on to learn about lean manufacturing's roots, goals, values and to see if it's time for your business to adapt a lean methodology. What is Lean Manufacturing? Lean manufacturing is a method of production that aims to reduce waste while maintaining productivity and increasing customer satisfaction. The idea originated over a century ago on the Ford factory line, but its practices hold strong in manufacturing and its principles have even carried over into business management philosophy. Find out more... |

|

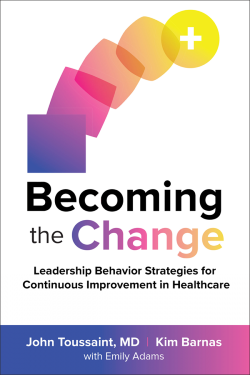

John Toussaint and Kim Barnas Receive Shingo Publication Award for Becoming the Change The Lean Enterprise Institute celebrates that The Shingo Institute, a program of the Jon M. Huntsman School of Business at Utah State University, has awarded John Toussaint, MD, and Kim Barnas the Shingo Publication Award for their book, Becoming the Change: Leadership Behavior Strategies for Continuous Improvement in Healthcare. Toussaint, a pioneer in adopting lean thinking and practice in the healthcare industry, served twelve years as an LEI Board Member until mid-2001. LEI copublished the book in collaboration with McGraw Hill and Catalysis Inc., a nonprofit dedicated to positively transforming the healthcare industry through organizational excellence. Receipt of the award “signifies an author’s significant contribution and practical application to the body of knowledge regarding organizational excellence,” says Ken Snyder, executive director of the Shingo Institute.  Becoming the Change is a powerful new approach to healthcare leadership. Drawing on a wealth of behavioral research, industry case studies, and personal insights from healthcare professionals, the two renowned healthcare transformation experts provide a practical blueprint for implementing the principles and behaviors leaders at all levels must embrace to create more value within the healthcare industry. The book highlights executives in health systems around the world as they practice behavior-based solutions to organizational problems, support continuous improvement, reflect and assess themselves as leaders, and achieve better results for patients. John Toussaint and Kim Barnas demonstrate that “the key element in any sustainable transformation is new beliefs and management practices by leaders,” said James P. Womack, PhD, founder and senior advisor at Lean Enterprise Institute. “They offer a plan for every healthcare leader to truly become the change in the quality and productivity of their organization—along with enhanced patient and employee experience—by first changing their own behavior. It isn’t easy and it requires perseverance, but it is possible, and Becoming the Change shows how.” Commenting on the award-recipient book, John Shook, chairman of Lean Global Network, said, “Personal transformation without organizational transformation is difficult. It isn’t easy to be an island of lean thinking surrounded by a turbulent sea of conclusion-jumping followed by analysis paralysis. ‘Becoming the change’ means exactly that: the transformation we so desperately need today will occur only when those of us who lead embrace the transformation personally.” The authors will receive their award at the Awards Gala during the Shingo Conference in Provo, Utah, USA, on May 23, 2023. The conference features benchmarking tours, workshops, keynote speakers, and interactive break-out sessions designed to provide ongoing knowledge, insights, and experience for organizations pursuing operational excellence. To learn more about the conference, please visit https://shingo.org/events.To order your copy of Becoming the Change: Leadership Behavior Strategies for Continuous Improvement in Healthcare, visit https://www.lean.org/s=becoming+the+change. About the Lean Enterprise InstituteLean Enterprise Institute Inc. is a 501(c)(3) nonprofit based in Boston, MA, with a mission to make things better through lean thinking and practice by helping companies create more value and prosperity while consuming the fewest possible resources. Founded in 1997 by management expert James Womack, PhD, LEI conducts research through co-learning partnerships with companies, teaches on-site and online workshops, publishes books and ebooks, organizes conferences, and shares practical information about lean thinking and practice at www.lean.org. About the Shingo Institute The Shingo Institute is home of the Shingo Prize, an award that recognizes organizations that demonstrate an exceptional culture that fosters continuous improvement. Part of the Jon M. Huntsman School of Business at Utah State University, the Shingo Institute is named after Japanese industrial engineer and Toyota adviser, Shigeo Shingo. Dr. Shingo distinguished himself as one of the world’s thought leaders in concepts, management systems, and improvement techniques that have become known as the Toyota Production System. Drawing from Dr. Shingo’s teachings and years of experience working with organizations worldwide, the Shingo Institute developed the Shingo Model, which is the basis for its several educational offerings, including workshops, study tours, and conferences. Workshops are available in multiple languages through the Institute’s Licensed Affiliates. For more information on workshops, affiliates, or to register to attend the Annual Shingo Conference, please visit www.shingo.org. Media Contact:Matt Savas Director of Content Lean Enterprise Institute 508-612-1527twitter | linkedin |

|

Veteran Events Executive Returns to the Lean Enterprise Institute The nonprofit Lean Enterprise Institute (LEI), a global leader in lean management thinking, practice, and innovation, announced that Rachel Regan, a veteran lean practitioner and events director, has rejoined LEI as executive director of events. She will oversee the development of the annual Lean Summit and other gatherings, including executive forums and in-person and online workshops.  Rachel Regan rejoins the Lean Enterprise Institute as executive director of events. Regan’s extensive lean and continuous improvement experience includes stints as a quality engineer at Toyota Motor Manufacturing (Georgetown, Kentucky), lean consultant with Total Systems Development, and events director for LEI, where she also served as the education manager and operations manager. In addition, she’s a Shingo Prize Examiner, contributing author to Lean Manufacturing: A Plant Floor Guide (SME, 2001), and author of various blogs and articles about lean thinking and practices. At Toyota, she worked on the corporate Supplier Improvement Committee, which helped Toyota’s North American suppliers improve quality and delivery, and was responsible for final vehicle quality. As a lean consultant, she worked with global companies in the automotive, footwear, and farm equipment industries. Since 2003, she’s targeted her expertise toward building highly engaging events that educate and inspire practitioners in their pursuit of excellence through lean thinking and practice. She played a prominent role in developing LEI’s practitioner-to-practitioner programming, which promotes peer-based learning.

In her most recent role at Catalysis, Inc., which promotes lean methods and mindsets to transform healthcare delivery, she oversaw the annual Lean Healthcare Transformation Summits in the U.S. and Europe and Physician Lean Leader Forums. For these events, she developed the strategy and program to produce a learning experience that included the social and technical elements of lean leadership and management. Strengthening the Lean CommunityIn announcing Rachel’s return to the Institute, LEI President Josh Howell highlighted Regan’s contribution to the lean community. “The vitality of the Lean Community comes from veteran and new members alike. Rachel is one of the veterans who deeply understands the value of community gatherings like LEI’s Lean Summit,” he said. “We are thrilled to have Rachel returning to the helm of LEI’s signature event, especially after its three-year hiatus.” “I believe that we can learn more and progress faster and better together than we can alone,” Regan said. “The Lean Enterprise Institute is the premier convener of lean practitioners, and I’m excited to help further the mission of LEI and support the lean community through my work with events.” About the Lean Enterprise InstituteLean Enterprise Institute Inc. is a 501(c)(3) nonprofit based in Boston, MA, with a mission to make things better through lean thinking and practice by helping companies create more value and prosperity while consuming the fewest possible resources. Founded in 1997 by management expert James Womack, PhD, LEI conducts research through co-learning partnerships with companies, teaches on-site and online workshops, publishes books and ebooks, organizes conferences, and shares practical information about lean thinking and practice at http://www.lean.org. Matt Savas |

|

Education Entrepreneur Valeriia Zabolotna Joins the Nonprofit Lean Enterprise Institute The nonprofit Lean Enterprise Institute (LEI), a global leader in lean management thinking, practice, and innovation, today announced the hiring of Valeriia Zabolotna as executive director of education. She will lead the business strategy and curriculum development for LEI’s educational products and services, including live and online courses, workshops, and new offerings.  A former board member of the Lean Institute Ukraine, Zabolotna brings a unique combination of extensive experience in founding and leading educational institutes and knowledge of lean thinking and practices. With expertise in organizational psychology and innovative educational approaches, she has founded and led four leading-edge educational institutions, playing an integral role in curriculum development, staffing, funding, and operations. Her experience includes all stages of education as a teacher, owner, and leader, from kids to adults, from a school to a corporate setting. “It’s rare to meet someone as accomplished and innovative as Valeriia, especially when it comes to education. Her leadership and ideas will enable LEI to provide experiential lean learning at scale, consistent with our mission to make things better by creating as many lean thinkers and practitioners as possible,” says LEI President Josh Howell. Innovating Education “I’m always in search of new approaches, formats, and methods that keep up with the change in the world,” Zabolotna says. Examples include two revolutionary schools she established in Kiev, Ukraine, which developed over 10 thousand software engineers, using unique approaches involving no teachers or schedules. She has also served as president of two corporate universities for the biggest companies in their sector in two countries. At an energy company’s Academy, Zabolotna established an open educational platform to attract external students, which improved its financial performance and profile. She also reorganized the team working on an alternative Lifelong Learning methodology in response to the rapidly changing environment. At a bank, in addition to overseeing educational programs for the organization’s 300,000 employees, she enhanced the Corporate University’s stature and visibility by arranging international accreditation from the Global Council of Corporate Universities and The European Foundation for Management Development and developing international relationships with Stanford, Berkeley, Insead, and other top universities. Zabolotna earned a Doctor of Philosophy in Ethics and a master’s degree in Psychology from Kiev State National (Taras Shevchenko) University. Also, she holds a Master of Business Administration in Electronic Commerce from the University of New Brunswick, Saint John, NB. About the Lean Enterprise Institute Lean Enterprise Institute Inc. is a 501(c)(3) nonprofit based in Boston, MA, with a mission to make things better through lean thinking and practice by helping companies create more value and prosperity while consuming the fewest possible resources. Founded in 1997 by management expert James Womack, PhD, LEI conducts research through co-learning partnerships with companies, teaches on-site and online workshops, publishes books and ebooks, organizes conferences, and shares practical information about lean thinking and practice at http://www.lean.org. |

|

Operations Leader Joins the Nonprofit Lean Enterprise Institute The nonprofit Lean Enterprise Institute (LEI), a global leader in lean management thinking, practice, and innovation, today announced the hiring of Tammy M. Wilkins as executive director of administration. Wilkins is an experienced executive with deep firsthand experience implementing operational improvements and business transformation that yielded positive results for organizations such as American Express, Ashland Oil, Toyota Motor Manufacturing, and the nonprofit National Minority Supplier Development Council.  Wilkins will oversee human resources, finance and accounting, information technology, and business and office operations, leading the administrative staff in improving the execution of these functions. Wilkins has over 30 years of experience deploying enabling technology and leading strategic initiatives to improve complex, cross-functional operations involving core business functions, including HR, IT, Marketing and Communications, Legal, Accounting and Finance, and Procurement. She also led large-scale conference planning and execution. Talent and Experience“Tammy brings a great set of personal and professional attributes to LEI,” said Peter Ward, LEI Board Chairman. “As LEI continues to grow in its reach and influence, an administrative leader like Tammy — who brings a keen focus on people, process, technology, and data to her work — is needed to work with and serve LEI’s terrific administrative team. With her extensive and broad range of experience across administrative functions at great organizations, she’ll fill a vital, core role leading improvement in LEI’s processes.” “The Toyota Production System 14 lean principles continues to be a part of my DNA. These principles, if implemented properly, are the key for achieving operational excellence; once you learn and apply these principles, they become integrated into your daily thinking process,” Wilkins said. “It is my honor to join the LEI and focus on its operations as the organization continues to introduce lean thinking and lean practices through organic partnerships.” About the Lean Enterprise InstituteLean Enterprise Institute Inc. is a 501(c)(3) nonprofit based in Boston, MA, with a mission to make things better through lean thinking and practice by helping companies create more value and prosperity while consuming the fewest possible resources. Founded in 1997 by management expert James Womack, PhD, LEI conducts research through co-learning partnerships with companies, teaches on-site and online workshops, publishes books and ebooks, organizes conferences, and shares practical information about lean thinking and practice at http://www.lean.org. |

|

Finding Practical Continuous Improvement Information Is Easier and Faster on the New Lean Enterprise Institute Website Improved navigation and functionality at the new lean.org, which launched September 21, 2021, make it easier and faster for businesses to find comprehensive content about continuous improvement. Lean Enterprise Institute, Inc., a global leader in lean management thinking, practice, and innovation today announced the launch of its improved website, https://www.lean.org/. The completely redesigned site boasts improved functionality and better navigation that makes finding the site’s comprehensive content about continuous improvement in a variety of industries much easier and faster. The new website’s clean, modern aesthetics make for better readability and appearance on multiple devices. Designed for both experienced and new lean management practitioners, the new website is organized for business people who want to:

Anyone seeking to continuously improve customer satisfaction, lead time, costs, quality, new product development, and other key business performance measures—managers, executives, engineers, and continuous improvement professionals in manufacturing and service industries—will benefit from the many articles, books, blog posts, multi-media content, and training resources on the site. About the Lean Enterprise Institute Lean Enterprise Institute Inc. is a 501(c)(3) nonprofit based in Boston, MA, with a mission to make things better through lean thinking and practice by helping companies create more value and prosperity while consuming the fewest possible resources. Founded in 1997 by management expert James Womack, PhD, LEI conducts research through co-learning partnerships with companies, teaches on-site and online workshops, publishes books and ebooks, organizes conferences, and shares practical information about lean thinking and practice at http://www.lean.org. |

|

A3 Problem Solving | A3 Root Cause Analysis Problems are inevitable, no matter how hard we plan and what precautions we take, they will eventually creep up and bite us. Rushing in and trying to fix the problems quickly, however, rarely seems to truly make these problems go… The post A3 Problem Solving | A3 Root Cause Analysis first appeared on Lean Manufacturing Tools. |

|

Lean Consulting and Support Not every business or up and coming lean facilitator has the money to pay a consultant potentially thousands of dollars a day to come and provide the help and support that they are looking for. Nor do they necessarily want… The post Lean Consulting and Support first appeared on Lean Manufacturing Tools. |

|

One on One Lean Coaching Online One on One Support Improving your processes can be difficult if you do not know where to start, as can be implementing Lean Manufacturing Tools such as 5S or Value Stream Mapping. Our online coaching for Lean however could be… The post One on One Lean Coaching Online first appeared on Lean Manufacturing Tools. |

|

Setup Reduction SMED Coaching “Send me a video and I will help reduce your setup times” Reducing setup time is a vital part of most Lean implementations if you want to be able to reduce batch sizes and improve process efficiency. SMED as the… The post Setup Reduction SMED Coaching first appeared on Lean Manufacturing Tools. |

|

Lean Process Improvement Coaching “Send me a video of your process and I will help make it more efficient” One of the most common areas that companies are looking for when looking for any form of lean support is to improve their process efficiency.… The post Lean Process Improvement Coaching first appeared on Lean Manufacturing Tools. |

|

Value Stream Mapping of a Complete Product Profile: Shahrukh A. Irani and Jin Zhou Introduction: Lean Thinking, a concept that is based on the Toyota Production System, extends continuous improvement efforts to reduce the costs of serving customer/s beyond the

Value Stream Mapping (VSM) is the process of mapping the material and information Please click here for the details: Value Stream Mapping of a Complete Product.pdf

|

|

Value Network Mapping (VNM) Visualization and Analysis of Multiple Flows in Value Stream Maps Profile: ZahirAbbas N. Khaswala and Shahrukh A. Irani 1 Outline of this Paper First, the concept of Lean Thinking is introduced and reviewed. This is followed by an explanation of the basic concepts of Value Stream Mapping (VSM), with a listing of the advantages and disadvantages of VSM. Specifically, it is shown that the original VSM methodology breaks down in the case of "multiple flows in a value stream that merge" in the case of complex product BOMs. Next, the development of the proposed approach, Value Network Mapping (VNM), is explained in detail. Finally, the results from an industry project are analyzed and the potential benefits of the proposed approach are presented. Please click here for the details: Value Network Mapping (VNM).pdf

|

Flow of Product to Consumer

Used with kind permission from the book: "Mechanism of a Factory with Illustrations" Published by Nippon Jitsugyo Publishing. by Mitsuo Matsubayashi and Hiroshi Watabe. Members of Waku Consulting Co. Ltd Please click here for the web site of Waku Consulting. |

Flow of Material and Information through the Factory

Used with kind permission from the book: "Mechanism of a Factory with Illustrations" Published by Nippon Jitsugyo Publishing. by Mitsuo Matsubayashi and Hiroshi Watabe. Members of Waku Consulting Co. Ltd Please click here for the web site of Waku Consulting. |

Operation Flow of Whole Factory

Used with kind permission from the book: "Mechanism of a Factory with Illustrations" Published by Nippon Jitsugyo Publishing. by Mitsuo Matsubayashi and Hiroshi Watabe. Members of Waku Consulting Co. Ltd Please click here for the web site of Waku Consulting. |